Development ALUWAG

Trial connecting rods

Over the last few years, we have been working hard to develop special materials in die casting. The wide range of special materials offering higher chemical and physical properties, as against standard materials, have allowed us to realize development projects with highest requirements.

The connecting rods are manufactured in the die casting process and heat treated. It demonstrates the high elongation at increased strength of the ALUWAG material. With the special materials, we have implemented projects in the powertrain, steering range and also car bodies (safety component).

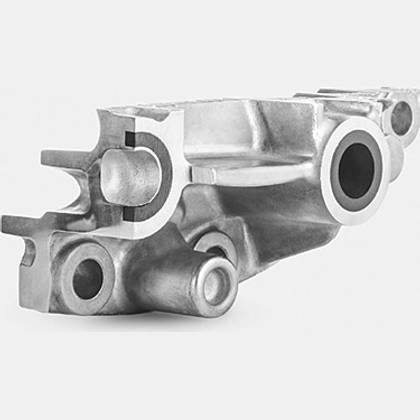

Manifold

Manifold

Piston

Piston

Electric-engine housing

Electric-engine housing

Electronic Housing

Electronic Housing

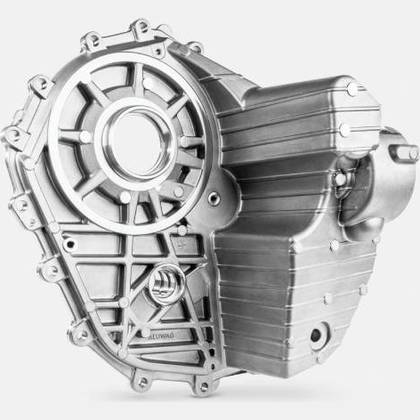

Stator carrier

Stator carrier

Stator carrier

Stator carrier

Stator carrier

Stator carrier

Rear axle steering (AKC) housing cover

Rear axle steering (AKC) housing cover

Basic Automotive Body

Basic Automotive Body

Clutch carrier

Clutch carrier

Connection plate

Connection plate

Oil pan

Oil pan

Oil pan

Oil pan

Trial connecting rods

Trial connecting rods

Trial plastic aluminum hybrid

Trial plastic aluminum hybrid

Bracket

Bracket

Strut

Strut

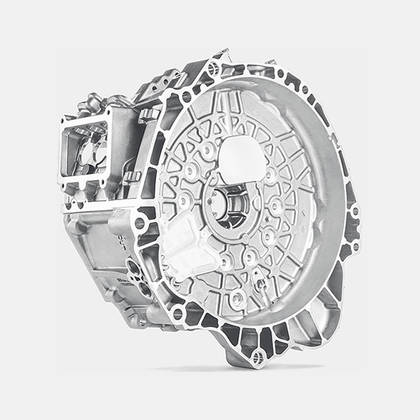

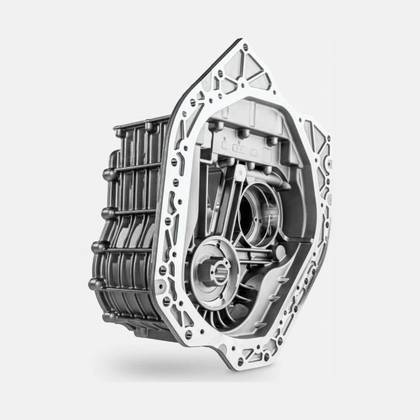

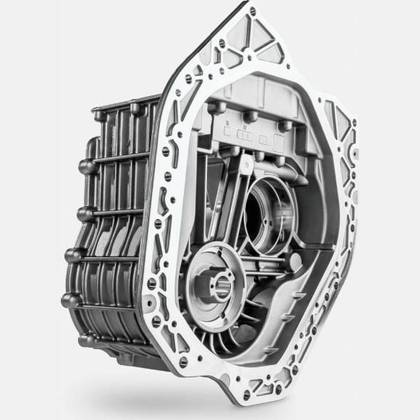

Transmission Housing

Transmission Housing

Transmission Housing

Transmission Housing

Bottom Part

Bottom Part

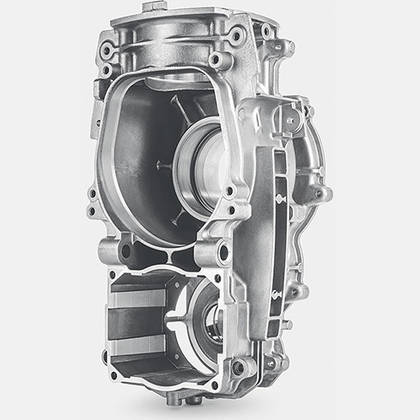

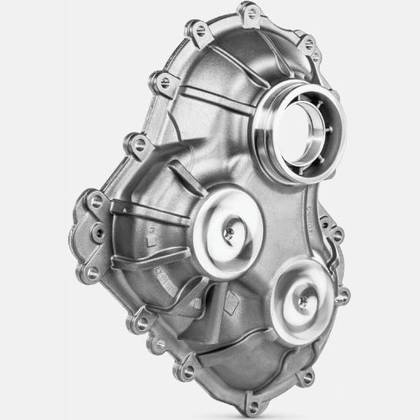

Intermediate Housing

Intermediate Housing

Top Part

Top Part

TFM Chassis Top

TFM Chassis Top