Digital Brochure

Learn more about ALUWAG in our interactive brochure.

View now

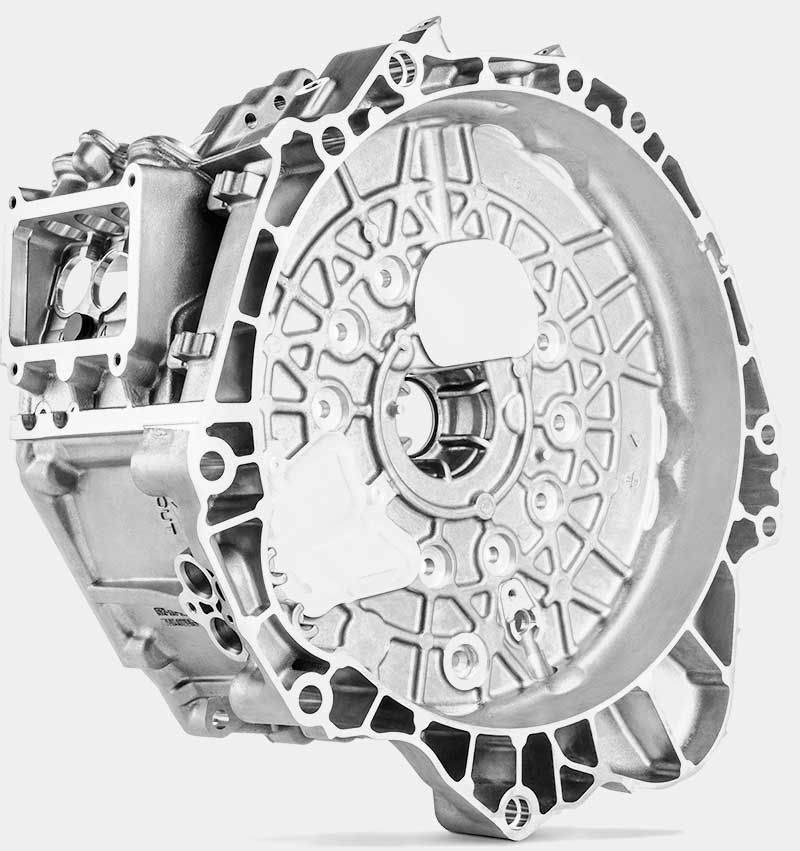

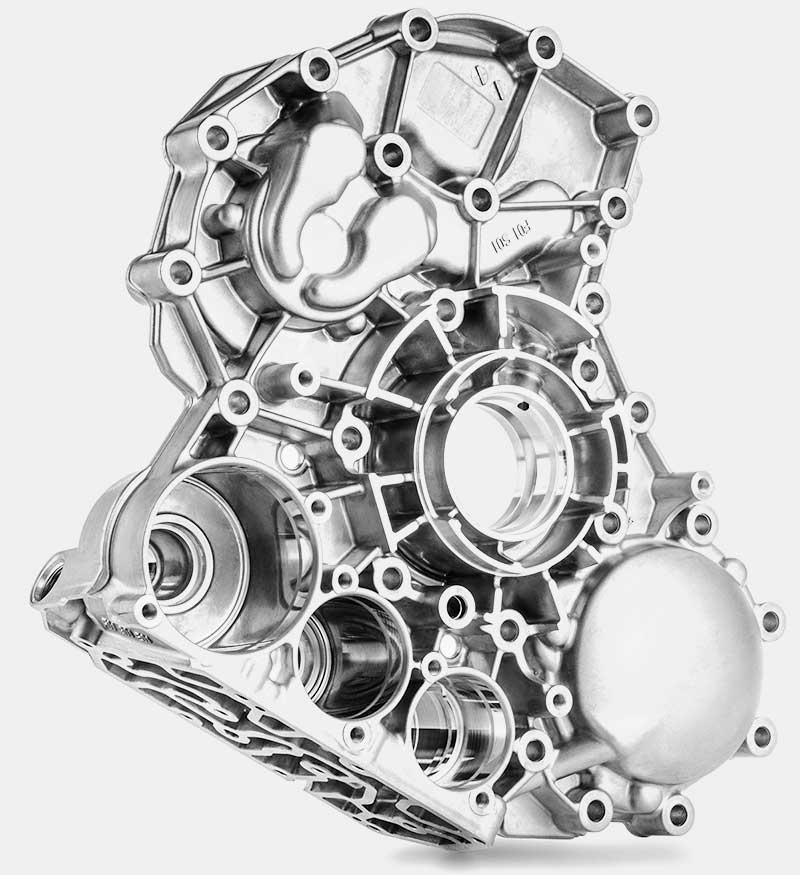

Individual die casting solutions emerge as part of a comprehensive and structured process that stretches from the analysis and development stages to production and finishing. In the product-related process, research and development as well as consulting and support are also implemented. Furthermore, the entire process is secured by continuous quality management. During the initial analysis, we look at the needs and expectations of our customers in detail.

Within the comprehensive overall process, analysis is followed by the development stage. Here, a focus is placed on materials technology, engineering and laboratory activities that, for example, comprise state-of-the-art CT and spectral analyses as well as prototyping and sampling.

Within the value chain, development is followed by fully automated production. Here, we systematically pursue a zero-error strategy, which we guarantee for any requested quantity. This quality awareness is part of our corporate self-image that is also expressed in our quest to achieve continuous process and cost optimization.

Standard solutions generate standard results. This is not what we or our customers want. Within the framework of the overall process, we therefore offer diversified finishing work after production. This includes heat treatment and joining technology, mechanical processing and state-of-the-art surface technologies. We also ensure assembly up to the finished component or the desired module.